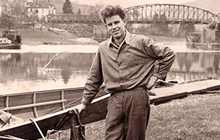

Jakob Kaschper started his career as a Rowing Shell Designer and Manufacturer at a young age. He served a rigorous Apprenticeship in his home town of Eberbach, Germany, at Empacher Boatworks. He completed his Journeyman's project (see photo) and received his certification papers at age 19. After working as a builder and designer for Willy Empacher for a time, Jakob emigrated to Canada. When he arrived in Ontario in 1958 he began building singles and eights of his own design in an old barn on Lake Fanshawe for London Rowing Club. After 10 years of working and saving, he started his own Boatworks just north of London in Lucan, Ontario.

Kaschper Racing Shells was begun as a Limited Corporation in 1969. Jakob Kaschper spent most of the first year designing and constructing moulds for singles through eights. Through the 1970's wood construction of rowing shells was still dominant. In the early 80's Kaschper introduced the first composite hulls in North America featuring a semi transparent hull lined with carbon fiber or carbon matrix material. One of these boats, affectionately know as Tiger or Zebra shells, was commissioned by the Ontario Science Center and remains on display in the Technology Exhibit for that time period. This new carbon construction proved to be extremely light in weight, and before FISA dictated minimum boat weights, Jakob had produced a remarkable 198 lbs sectioned eight, which was raced by the Canadian National Team at the World Championships in Munich, Germany in 1988.

Moving ahead into the 90's, we see the introduction of wood/composite Vak Shells, and then fully composite shells with no wood infrastructure. The complete design switch from traditional Side Rigged shells to Wing Rigged shells (originally developed by Ted Van Dusen for the 1x) was completed in 1995. New moulds for the Wing Rigged designs from 1xs to 8+s were built. The new shells were to be built with new composite materials requiring Oven Curing, and a NEW Computerized 70' long Curing Oven was built and put into production in 1997. Advancements in composites technology continued, and Kaschper adjusted to and embraced newer and better materials and processes for boat production as developed in aerospace manufacturing.

In 2018, Kaschper Racing Shells celebrates 50 years in business. The company has developed many advanced innovations to rowing shells, using the latest in high temp cured, epoxy resin infusion techniques, to produce light, strong, 100% carbon racing shells. Design innovations like the Bio Rig, Vanguard, use of Titanium, and others, have defined the mission and goals of the company from it's inception. The company recently downsized to a smaller facility as many of the long term employees have retired. We still provide parts for Kaschper boats, but have a very limited boat production each year.

Jurgen Kaschper continues the long standing family tradition of fine craftmanship with his line of boats at Levator Boat Works in Dorchester Ontario. Jurgen has received awards for his design innovations, and creates 'one of a kind' shells using composites, wood, and combined

materials to build exceptional racing shells.